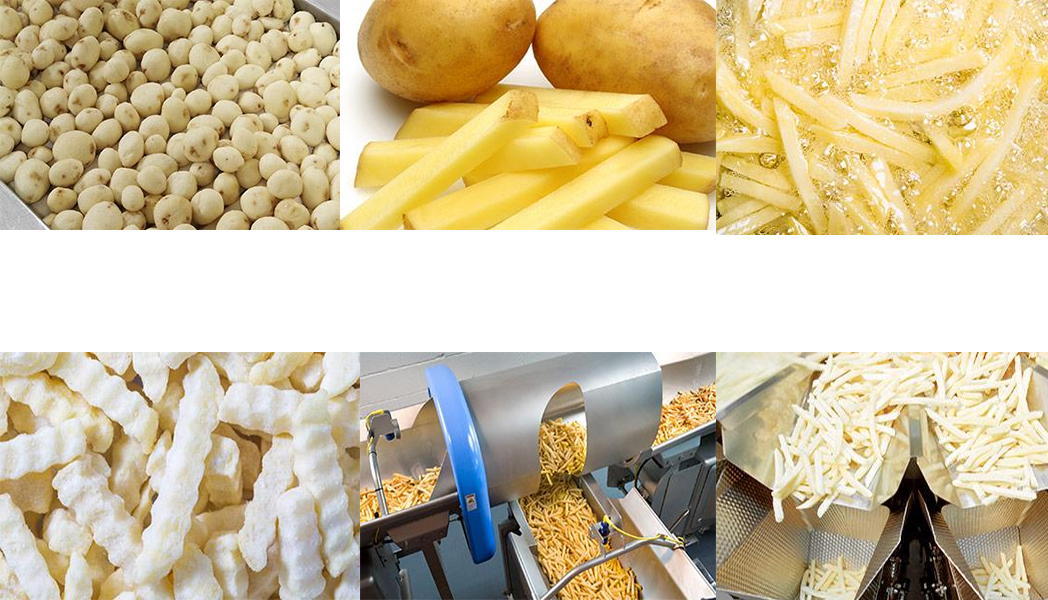

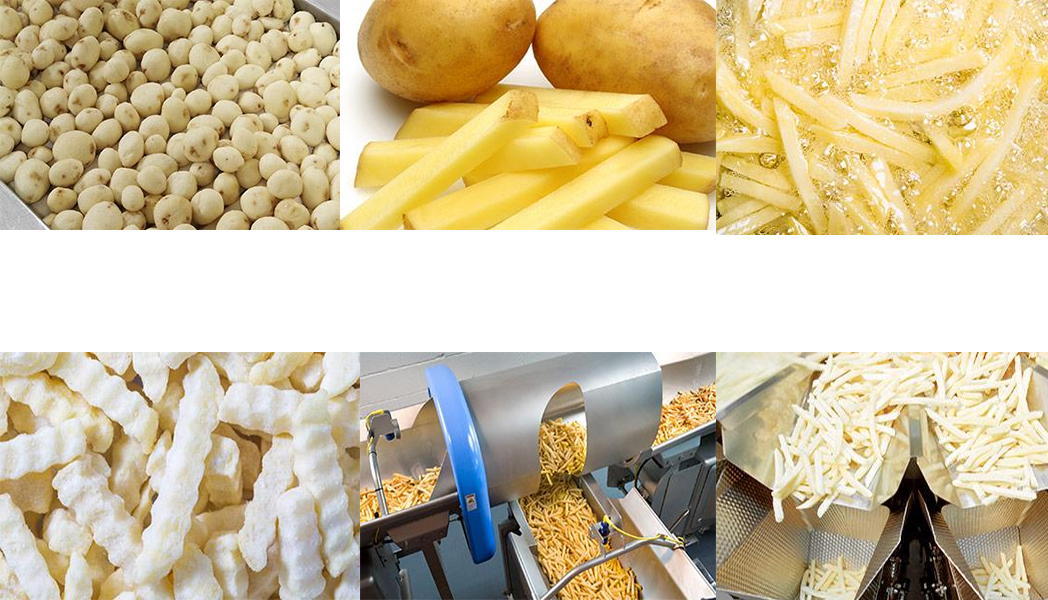

Our french fry and formed potato product systems are the workhorses of the industry. We process a broad range of styles, including straight cut fries, crinkle cut fries, curly fries, potato wedges, and variety of potato co-products. Working with our strategic partners, we are capable of full turnkey solutions, from potato receiving through palletizing.

Potato Unloading & Storage

Raw potato handling is simplified as it enters the facility with equipment to unload and store potatoes prior to processing. Truck dumpers, dirt removers, transfer, and bin storage systems handle large volumes of potatoes easily and gently. Working with our strategic partners, we are capable of full receiving area solutions.

Potato Handling

Transfer, feeding, and potato pumping water flume systems handle large volumes of potatoes easily and gently meter potatoes to processing. Working with our strategic partners, we are capable of complete handling solutions.

Peeling / Grading

Achieve peeling control and high yield with batch or continuous peeling systems that deliver polished peeled potatoes and minimal peel loss. Inspection conveyors provide operator friendly access and full visual inspection. Working with our strategic partners, we are able to supply steam peeling, potato washing, and whole potato sorting solutions.

Cutting

Whether it’s preparation for delivery to the slicer or slicing the myriad of french fry styles you need, we provide a variety of cutting systems. Working with our strategic partners, we are capable of supplying mechanical and hydro cutting solutions/systems.

Frying

We provide more choices when it comes to selecting a new fryer. Choose from natural gas, oil, steam, thermal fluid or electric heating. Optimal product handling, uniform oil heating and flow control, efficient fines removal, fast oil turnover, and clean-in-place sanitation are all part of the fryer package that produces the highest quality product with a long shelf life.

Fryer Support Module

Significantly reduce the time and cost of fryer system installation by centralizing oil pumps, filters, valves, piping, and other components on a Fryer Support Module.

Oil Heating

Our cooking oil heating and energy recovery systems are designed to provide high energy efficiency, preserve the quality of the cooking oil, and maintain accurate temperature control for uniform cooking.

Oil Removal

Remove surface-oil prior to freezing and packing. Recover frying oil and minimize oil waste to realize significant cost savings, increased yields, and a healthier product.

Oil Cooling

Save time by managing the cooking oil cooling process as you prepare the fryer for shut-down or sanitation. This also helps preserve cooking oil quality.

Freezing / Cooling

Control the end of the cooking cycle by effectively managing the temperature of your cooked product. This ensures high quality as well as prepares it for the next stage of your process, such as seasoning or packaging. Along with our strategic partners, we offer freezing tunnels and spiral freezers for complete processing and packaging solutions.

Seasoning

Our unbeatable seasoning showcase includes a variety of systems that provide consistent and uniform seasoning coverage for french fries.

Conveying

Our conveying and product handling systems include product transfer systems, horizontal motion conveyors, and accumulation systems that provide a gentle, smart, and dependable product transfer solution.

Weighing

Ishida has a long history in weighing innovation and revolutionized the industry with the invention of computer combination weighers that reduce product giveaway. Weigh at the highest speeds and lowest lifecycle costs, and interface with any packaging equipment to maximize weighing productivity.