Specialized In R&D For Individual Quick Freezing Equipment

Capacity :100-500kg/h customzied as your need.

Material :304 Stainless Steel

Production Name:Automatic Potato Chips Production Line

All cooperative partners operate well

Specialized In R&D For Individual Quick Freezing Equipment

Capacity :100-500kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel

Production Name :Automatic Potato Chips production line

All cooperative partners operate well

Specialized In R&D For Individual Quick Freezing Equipment

Capacity :100-500kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel

Production Name :Automatic Potato Chips Production Line

All cooperative partners operate well

Specialized In R&D For Individual Quick Freezing Equipment

Capacity :100-500kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel

Production Name :Automatic Potato Chips Production Line

All cooperative partners operate well

Specialized In R&D For Individual Quick Freezing Equipment

Capacity :100-500kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel

Production Name :Automatic Potato Chips Production Line

All cooperative partners operate well

Introduce

Production Process

Parameter

Process Display

Characteristic

Advantage

Customer Case

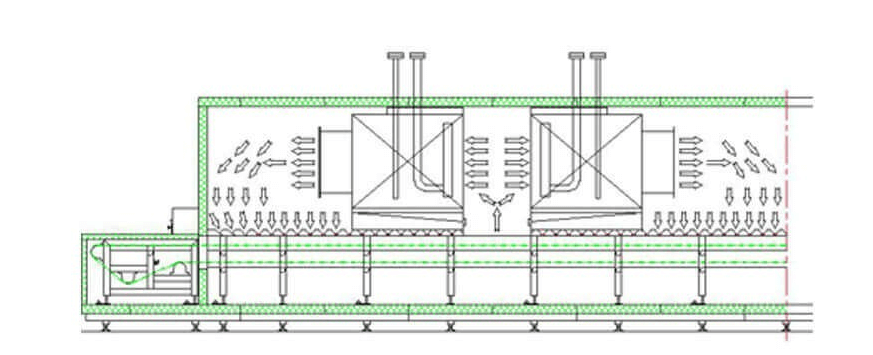

The versatile IQF tunnel range efficiently produces high-quality IQF products without compromising cost, footprint, or quality. Seamless integration into a continuous or automated production line is possible. It consistently delivers high-quality results while preserving the products’ nutritional value, shape, colour, smell, taste, texture and moisture level even after the end-user defrosts the product at home.

Coils provide excellent heat transfer with rapid and efficient water or hot gas defrosting, including an automatic defrosting system.

An evaporator with varying fin spacing eliminates the problem caused by product debris blocking the evaporator fins.

Infrequent and easy maintenance due to the robust construction and unrestricted access to all parts.

|

Model |

Freezing |

Freezing |

Cooling |

Size |

|

SZ-1TF150 |

150 |

10-100 |

34kw |

76*25*25cm |

|

SZ-1TF300 |

300 |

3.75kw |

65kw |

|

|

SZ-1TF500 |

500 |

9.55kw |

|

166*25*25cm |

|

SZ-2TF500 |

500 |

19.8kw |

99kw |

92*39*29cm |

|

SZ-2TF1000 |

1000 |

20.2kw |

175kw |

180*42*28cm |

|

SZ-2TF1500 |

1500 |

28.6kw |

256kw |

240*42*28cm |

|

SZ-2TF2000 |

2000 |

28.6kw |

326kw |

76*25*25cm |

1.Types of frozen products

2.Quantity of quick-frozen products

3.Freezing time

4.The temperature of the food before quick freezing?

5.The core temperature of the goods after quick freezing?

The continuous quick-freezing mode of tunnel freezer is suitable for large-volume processing and productionin factory assembly lines. It has strong quick-freezing capacity, simple operation and high degree of automation.

IOF freezing can be more energy-intensive and may require a higher initial investment compared to traditional freezingmethods. However, the benefits of product quality and operational efficiency make it a valuable asset for factory andmaintenance managers committed to high standards. Also, the cost per product frozen will reduce as there wllbe lesswaste, less labour requirements and due to efficient production less energy used per product frozen.

IQF stands for Individual Quick Freezing. An lQF freezer is a specialized system designed to freeze individual pieces offood separately, preventing them from clumping together. This technology is crucial for maintaining the quality and easeof use of frozen products like fruits, vegetables, seafood, and diced meats

Factory managers in the food processing industry, particularly those dealing with fruits, vegetables, or portionedproteins, should be familiar with IQF technology as it significantly impacts product quality and marketability

High Automatic, low oil consumption, large capacity, Reduce labor costs and increase production efficiency.

Reliable Performance.Good shape with a smooth surface and uniform thickness. Besides,the potato chips thickness adjustable according to your requirements.

Consistent Temperature Control: Continuous fryers maintain a consistent frying temperature, ensuring even cooking and optimal texture.

The production line can be adjusted to handle different types of chips . potato, banana,cassava.sweet potatoes, carrots. and other root-stem vegetables) and flavors, The line can also be adjusted for French fries production.

Oil filtration system: integrated oil filtration systems help maintain oil quality , reducing the frequency of ol changes and ensuring a cleaner frying process.

Safe and Clean: all the potato chips machines are made of stainless steel, which accords well with healthy standards.