Customer Background

This customer sent an inquiry about small 600kg potato chips production line for upgrading his business. Production capacity is about 600kg per hour.

This food processing company is a large and influential local enterprise, and has been committed to providing high-quality food products to USA and surrounding areas. With the continuous growth of market demand, they urgently need to introduce advanced production equipment to improve production efficiency and product quality. After inspecting multiple suppliers in China, they finally set their sights on our potato chips production line.

The Course Of Cooperation

Communication details:

After receiving the customer’s inquiry, our sales staff contacted the customer within 12 hours. In the initial contact with the customer, we deeply understood the customer’s specific needs, including production capacity, product specifications, taste requirements, packaging form, etc. The customer has high expectations for the automation and production efficiency of the production line, and also hopes that the equipment can adapt to the local climate and power conditions in the USA.

Solution customization:

According to the customer’s needs, our technical team quickly customized a 600kg Potato Crisps Making Machine. We provided the customer with detailed equipment parameters, process flow and layout design, and repeatedly communicated and confirmed with the customer through video conferences and emails to ensure that the solution fully met the customer’s requirements.

Field visit:

In order to let customers have a more intuitive understanding of our equipment and production strength, we invited customers to our factory for a field visit. Customers spoke highly of our production workshop, equipment quality and technical level, and expressed their willingness to cooperate with us on the spot.

Contract signing:

After the final plan was determined, the two parties signed the contract smoothly after friendly negotiations. We promise to deliver the equipment on time and provide high-quality after-sales service and technical support.

Production and delivery:

During the equipment production process, we promptly sent the production progress to customers in the form of videos and photos. After the equipment was produced, we tested the machine according to the customer’s requirements, and then packed it in wooden boxes and shipped it after the customer ensured that the equipment was correct.

Ishida has a long history in weighing innovation and revolutionized the industry with the invention of computer combination weighers that reduce product giveaway. Weigh at the highest speeds and lowest lifecycle costs, and interface with any packaging equipment to maximize weighing productivity.

Introduction of Potato Chip Manufacturing Equipment in Iran

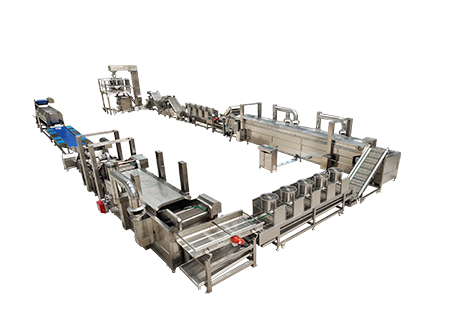

This Potato Chip Manufacturing Equipment in USA is large scale production line with high degree of automation. It consists of washing and peeling machine, sorting machine, slicing machine, blanching machine, dewatering machine, frying machine, oil draining machine, seasoning machine, as well as the packaging machine. Each machine has been carefully designed to ensure that the quality of the potato chips is stable and have a good taste.

Potato Chip Manufacturing Equipment in USA has an automatic oil temperature control function, which can ensure the frying effect of potato chips and improve production quality.

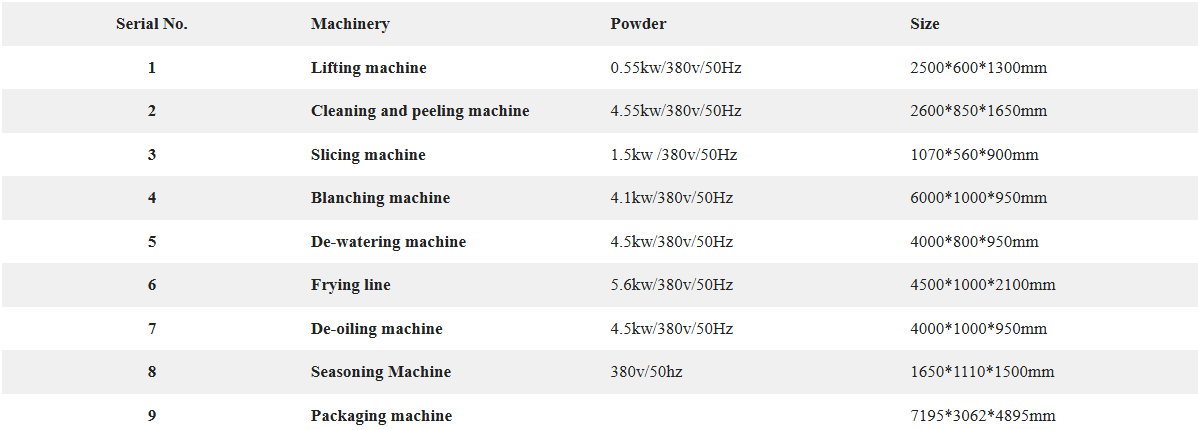

Machinery of Potato Chip Manufacturing Equipment in Iran

Delivery Photos Of Potato Chip Manufacturing Equipment In USA

Why Choose Our Potato Chip Manufacturing Equipment in Iran?

Technical strength: we have a strong technical R&D team and advanced production equipment, which can provide customers with customized solutions and high-quality products. Tell us your actual needs, and we will provide a customized potato chips production line solution to ensure that you buy the most suitable equipment, not the most expensive equipment.

Rich experience: With many years of production experience and technical accumulation in the field of food processing equipment, we can provide customers with professional technical support and after-sales service.

Quality assurance: All products undergo strict quality testing and certification to ensure compliance with international standards and customer requirements.

Thoughtful service: From pre-sales consultation, solution design, installation and commissioning to after-sales service, our company provides a full range of service support to ensure that customers can use the machine smoothly and achieve the expected production results.